Companies draft and utilize MEP drawings, which are part of architectural construction documentation, to ensure the smooth, safe, and timely completion of a project. These shop drawings incorporate civil, architectural, and structural components that make the construction process much easier.

In this article, we will discuss the different types of Mechanical, Electrical, and Plumbing (MEP) drawings and why they are the backbone of construction projects.

Table of Contents:

- The Role of MEP Drawings

- Detailed Shop Drawings: Annotations, Dimensioning, Elevations

- Penetration Drawings: Keeping the Structural Integrity Intact

- As-Built Drawings: The Post-Development Drawings

- Coordination Drawings: Detecting Obstructions

- Pipe Spool Drawings: Assembling the Pipes Accurately

- Conclusion

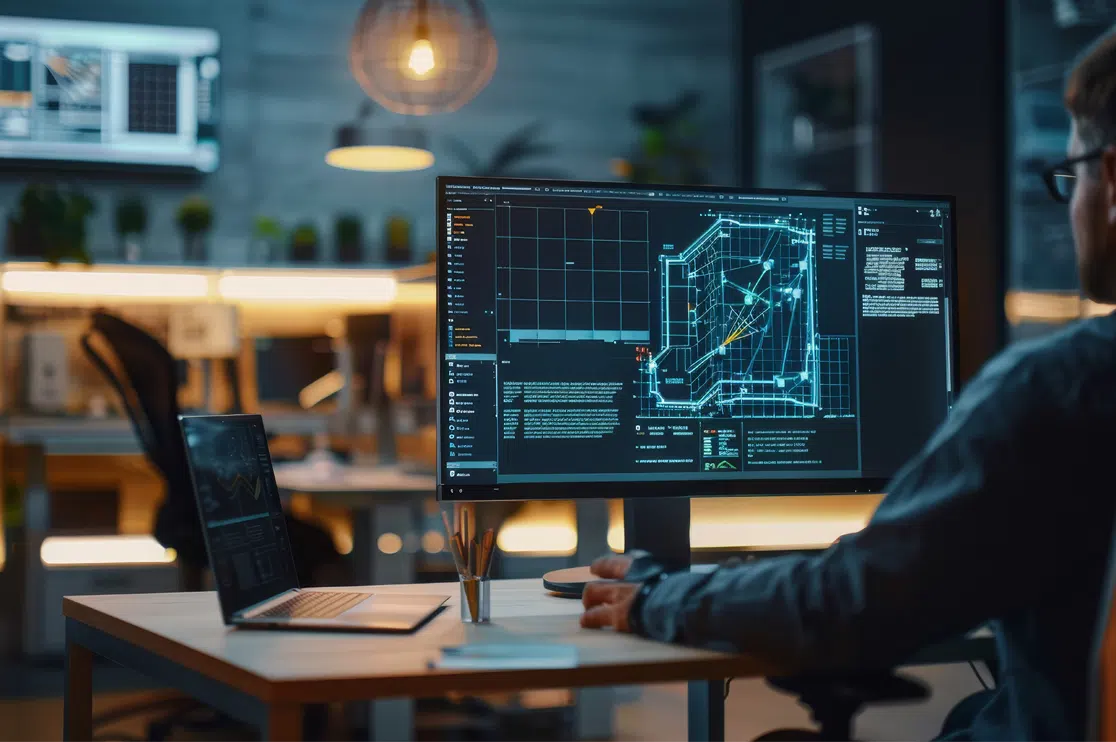

The Role of MEP Drawings

When planning a building’s construction, MEP shop drawings aid in the successful execution and performance of the mechanical, electrical, and plumbing systems.

These drawings present specific information and details of MEP elements, including the design, installation of fixtures, and functionality.

-

MEP drawings incorporate all relevant technical information about the wiring, piping, and HVAC (heating, ventilation, and air conditioning) systems needed to build any kind of residential or commercial building.

-

It is mostly used by equipment manufacturers, suppliers, and component vendors to gain clarity on the mechanical systems of the structure being constructed.

-

Subcontractors use MEP drafts as a measuring tool as they communicate the government standards required to construct the structure.

-

Companies mostly prepare MEP drawings using AutoCAD, Revit MEP, Autodesk Inventor, CAD PIPE, and CADDUCT.

-

These designs and drawing drafts are different for every structure and are created only after the building’s design documents are installed.

Precise and superior-quality MEP shop drawings are crucial to understanding how different elements must be successfully built and operated.

There are five types of MEP drawings. Let’s explore each type and why it is indispensable.

1. Detailed Shop Drawings: Annotations, Dimensioning, Elevations

Detailed shop drawings are created before the construction project and activities begin.

They are a highly detailed set of drawings for installing and fabricating the mechanical, electrical, and plumbing systems.

-

The MEP elements need pre-fabrication, which includes air-handling units, ductwork, custom piping units, etc.

-

The drawings provide accurate dimensions and are preferred over layout drawings and design details.

-

It helps in detecting any errors or inconsistencies before the final installation begins.

-

The shop drawings, created with standard codes, illustrate a clearer image of the project and step-by-step facilitation.

-

The detailed shop drawings help ensure that every element built in the off-site location will be manufactured without any mistakes.

The construction only begins after the team finalizes these models and drawings.

2. Penetration Drawings: Keeping the Structural Integrity Intact

Mechanical, electrical, plumbing, and structural systems are penetrants that are wedged into different floor and wall spaces.

The size of the openings through which elements such as electrical cables, pipes, electrical conduits, ducting, and cable trays pass is extremely important.

Penetration drawings help ensure that these items are located accurately. The precise dimensions given in the drawings facilitate this.

Once the penetration work is complete, any revisions to the drawings cannot be implemented. Therefore, MEP drawings must be thoroughly reviewed and approved to eliminate any chance of mistakes.

Communication and coordination between the project team members are crucial to ensuring the proper sizing of the openings.

3. As-Built Drawings: The Post-Development Drawings

Once the construction is finished, as-built drawings are created to help understand how the building was constructed.

These as-built MEP drawing sets give a clearer understanding of what was planned for the project and what was finally executed during the construction.

Recommended Reading:

The drawings are handed over to the client post construction. They include every detail of the building, fabrication, adjustments, and installation during the construction process.

These shop drawings offer in-depth information about the placement of the MEP components. They help in the facility management, building maintenance, repair, renovation, or refurbishment of any part of the building. The client also gains a better understanding of how the project was built.

4. Coordination Drawings: Detecting Obstructions

If a building project has many MEP regulations, the risk of interference between the three MEP systems is always high. They tend to collide during the installation or construction process.

This is where MEP coordination drawings play a significant role.

-

The Coordination MEP drawings help identify obstructions caused by the interaction between the mechanical, electrical, and plumbing work.

-

For example, these documents can help the team identify a severe clash between a water pipe and a duct before the installation process.

-

This gives the team a more vivid plan of action and helps restrict any physical conflicts in the equipment layouts, electrical piping, drainage channels, or duct routes.

-

-

It helps avoid structural problems, saves resources, time, and labor, and is known to be quite significant for the successful facilitation of any building construction project.

These MEP CAD drawings resolve any coordination issues, especially for complex MEP works.

5. Pipe Spool Drawings: Assembling the Pipes

Pipe spool drawings, sometimes also called piping isometrics, are shop drawings that provide a 3D view of a piping run. This enables shop personnel to fit and weld the piping runs properly. Every piping run has its own pipe spool drawing.

A pipe spool is a prefabricated element of a piping structure. The components, including flanges, pipes, and fittings, are usually built at the workshop before installation begins.

-

Generally, mechanical drafting teams create pipe spool drawings in various standard formats and give them to construction companies and site managers.

-

Pipe spool MEP drawings are created after gathering all the in-depth information on the elements welded together in one unified drawing.

-

These drawings are not to scale but consist of a graphical representation, title block, and bill of material.

-

These MEP drawings clarify what needs to be done for plumbers, who use them as a reference to understand and install the spools accurately.

-

Pipes are usually connected at multiple junctions in a building, and this document offers detailed information on assembling the spool properly.

-

The pipe spool drawings incorporate the number of pipes needed, their length, and where they need to be placed. They even showcase all the pipe fittings required for the process.

MEP drawings are important to reduce the complexities and challenges of the mechanical, electrical, and plumbing systems.

The benefits of an accurate set of shop drawings are virtually endless. They make the construction process much smoother and help save resources by minimizing or avoiding restructuring or corrections.

Does your construction project require MEP shop drawings? We recommend hiring a great shop drawing services provider like BluEntCAD, which can provide precise shop drawings.

BluEntCAD is one of the leading MEP drawing outsourcing companies in the world. Our team offers superior-quality drafting services with unparalleled precision. We serve home builders, real estate developers, architects, and home designers.

Browse our portfolio to see how we’ve helped companies like yours!

Let our precise MEP drawings and shop drawing service experts help you exceed client expectations and develop safe, efficient buildings.

To know more about our services or get a free consultation, connect with us!

Maximum Value. Achieved.

Must-Ask Questions Before Outsourcing CAD Drafting Services

Must-Ask Questions Before Outsourcing CAD Drafting Services  How BluEnt Ensures Construction Documentation is Accurate and Up-to-Date?

How BluEnt Ensures Construction Documentation is Accurate and Up-to-Date?  Why CAD Drawings Are Crucial for Sustaining the Modern Architecture Industry?

Why CAD Drawings Are Crucial for Sustaining the Modern Architecture Industry?  How is Artificial Intelligence in Construction Design Transforming Architectural Landscape?

How is Artificial Intelligence in Construction Design Transforming Architectural Landscape?

Issue with your heading after pipe spool drawings. Overall a good read tho!

Thank you for bringing that to our attention, Alex! It has been fixed.

If you would like us to cover anything else, do let us know at cad@bluentcad.com