In today’s Knowledge Series, we unearth details surrounding the precast concrete process, types of precast components, their features, and industries using this technology. We will also shed light on how precast detailing and fabrication shop drawing services help to pull off effective construction.

Table of Contents:

Precast concrete industry: A historical background

Precast concrete structures first appeared in the construction of underground tunnels in ancient Rome. The first documented history of modern precast concrete structures can be found through the efforts of an English engineer, John Alexander Brodie, in the early 20th century. He discovered that precast concrete components could create efficient structures by coming together.

In 1950, the iconic Walnut Lane Memorial Bridge in Philadelphia was constructed. It is widely believed to be the foundation of the precast concrete industry in US. Following the bridge, the Precast Concrete Institute was set up for standardizing the up-and-coming industry.

Precast detailing

Precast detailing is extensively used across the world for constructing commercial buildings, hospital infrastructure, stadiums, bridges, airports, etc. This kind of detailing offers several key features that are normally absent in other methods of concrete construction.

What is precast concrete?

Precast concrete is a construction product that is formed by casting concrete into reusable molds. It is then further cured in a controlled setting, transported to the site, and finally put into position.

Precast concrete materials maximize a project’s potential with quick turnaround time and by providing safer and more affordable structures than standard concrete. They are more versatile than several other construction materials because of their ability to:

- Take any color, form, or texture

- Integrate combination of different façades

- Adhere to compatibility benchmarks

- Manufacture everything – from small sections to large spans

- Be recyclable and reusable.

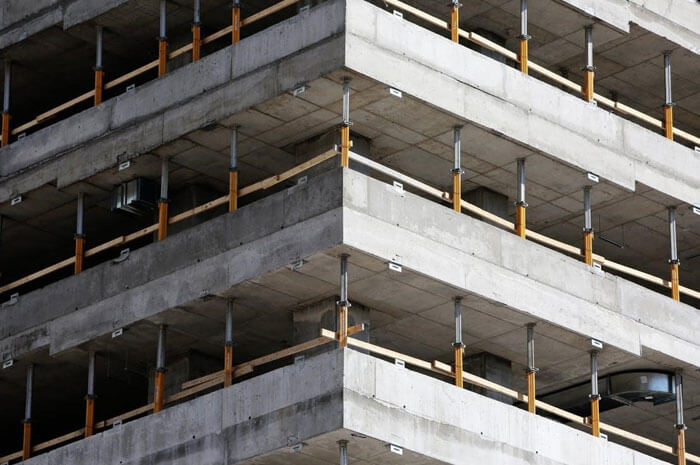

Components of precast concrete

Although there are many components that constitute precast structures, here are some major types that are common to most buildings:

- Precast beams: Internal beams with approximately symmetrical floor loading and external beams with predominantly non-symmetrical floor loading.

- Precast columns: Edge columns that are symmetrical in one direction, internal columns that are symmetrical in all directions, and corner columns that are not symmetrical at all.

- Precast floor slabs: Hollow cored slabs and double tee slabs.

- Precast walls: Infill walls that rely on a contiguous composite function between the column frame and beam, and cantilever walls that act as deep beams for attaching frames.

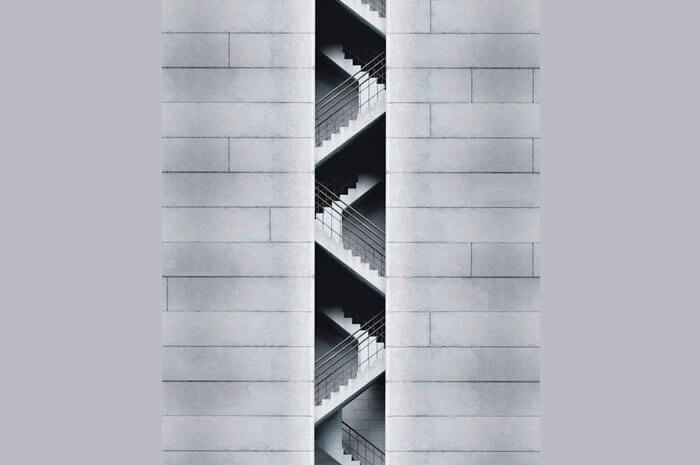

- Precast staircases: Single precast unit that contains all landings and flights, separate precast landings and flights, or a number of flights and landings joined as one piece.

Precast concrete structures, like other building designs, are achieved through concrete shop drawings, concrete panel shop drawings, and staircase shop drawings.

Precast concrete: Features of concrete shop drawings

Some of the salient features of concrete shop drawings are as follows:

- Precision in dimensional details and finishes

Precast detailing provides superior accuracy with respect to dimensions and finishes as compared to site-cast concrete. This is because of the controlled environment at the plant where the concrete components are cast – allowing contractors to exercise quality controls that follow regional and national production standards. Furthermore, there is no grout loss leading to poorly fitting framework.

- Ability to use commercial-grade elements

Using fabrication shop drawing services is the right solution to the problem of quality control, especially when there is difficulty in executing a production process on site.

Tasks such as formwork installation, reinforcements, and openings in staircases, lifts, and refuse chutes pose challenges, and lead to defects such as grout loss, inconsistent joints, and surface damage. With reinforced concrete drawings, staircase shop drawings, and concrete panel shop drawings, such defects can be reduced to a great extent.

- Concrete shop drawings offer greater design flexibility

Since the drawings are created prior to the actual production work, the elements can be designed to meet the design requirements. Complex shapes, sizes, and technical details can be incorporated in the design, checked for feasibility, and fabricated into the precast plant. These drawings can also be repeated for similar shapes and sizes in the future.

6-point checklist for designing the most effective concrete shop drawings

What 6 components are the most essential for getting your concrete construction drawings right? Our shop drawing experts reveal below:

- Component one: Architectural specifications

- Insulation: Insulated or non-insulated panels

- Supporting systems: Load-bearing or non-load-bearing panels

- Component two: Panel dimensions

- Weight restrictions

- Production limitations

- Stress limitations

- Feasibility and access of erection

- Size limitations

- Transportation weight

- Component three: Supporting structures

- Points where load is applied

- Erection stability

- Overall structural stability

- Component four: Standardization

- Incorporating maximum reuse of similar units to bring down the overall expense

- Component five: Detailed panel designing

- Reinforcing functions in their final positions, and for storage, transporting, stripping, and erection

- Designing connects, inserts, hardware lifting hooks, etc.

- Proportions of concrete mixture

- Component six: Shop drawings

- Pierce drawings

- Erection drawings

- Storage diagrams

- Special handling drawings

- Connect details

- Drawings for anchor layout

- Hardware detailing

For sound structural behavior, safety, and performance, proper precast detailing and concrete panel shop drawings are critical. However, design codes are not always easy to comprehend. This succinct checklist is beneficial for window manufacturers, curtain wall manufacturers, railing manufacturers, concrete subcontractors, and excavation sub-contractors for understanding and adhering to the design requirements.

A lot of innovation is happening in the AEC industry – from digitization to cloud services. Awareness of modern techniques and methodologies is essential for remaining one step ahead of your competition. BluEntCAD provides robust concrete shop drawings, construction drawings, and fabrication shop drawing services that adhere to industry standards for maximizing chances of success. To learn more about how our services can help you, get in touch with our shop drawing experts.

Maximum Value. Achieved.

AutoCAD And RFMS: Find the Perfect Fit for Your Tile & Stone Shop Drawing Projects

AutoCAD And RFMS: Find the Perfect Fit for Your Tile & Stone Shop Drawing Projects  Exploring the Array of Tile & Stone Shop Drawing Services: Choose Your Right Solution

Exploring the Array of Tile & Stone Shop Drawing Services: Choose Your Right Solution  Mastering the Tile Shop Drawing Workflow: How Precision Prevents Costly Delays and Chaos

Mastering the Tile Shop Drawing Workflow: How Precision Prevents Costly Delays and Chaos  On Time, Everytime! Reasons to Choose BluEnt as Your Tile & Stone Shop Drawing Partner

On Time, Everytime! Reasons to Choose BluEnt as Your Tile & Stone Shop Drawing Partner

Thanks for sharing very useful blog regarding to the Precast.

Thank you! If you would like us to cover any other topic, please reach out to us at cad@bluentcad.com