HVAC components are the backbone of any building. Comfortable temperatures, good air quality and energy efficiency are just a few of the benefits occupants receive when your duct shop drawings are done right.

This, of course, translates to higher ROI and greater trust in your brand.

And there’s good news.

Because of consistent growth in construction sector revenue (both private and publicly funded projects), the volume of the HVAC market will hit 151.1 million units by 2024. Furthermore, the MEP services market in the US is expected to expand from 2020 to 2025 at a CAGR of 16%.

But how do you get ductwork shop drawings right in the first place? Why do some HVAC duct systems flop while others don’t?

In this article, we’ll give you all the tools you need for your ductwork to succeed.

Table of Contents:

Many business and property owners don’t realize that HVAC systems and ductwork installation need to be charted out even before the architects complete the building plans.

HVACs are complicated systems. Even a small glitch means that the consequences will be time-consuming, messy and expensive.

Part of the advanced planning is to create a schematic through the right duct shop drawings that will allow contractors to figure out the right place to install the duct systems and related equipment.

Correctly installed ductwork provides both comfort and ease to the occupants.

What Are the Results of Poor Duct Design?

The US Department of Energy reports that HVAC duct systems inside buildings and hotels tend to be only 60% efficient.

This means that 40 properties out of 100 did not have the right duct shop drawings done before their construction, or did not implement them correctly.

Poorly constructed duct design leads to:

-

Drafts, stuffy air, and hot and cold spots because of inadequate air flow.

-

Additional load on air conditioners since they need to work harder and run longer due to compensating for ductwork design flaws. This leads to shorter appliance life and more malfunctions.

-

Sub-par air quality with more dust, fumes, pollutants and humidity, which can lead to mold and fungal growth.

-

Air pressure that is unbalanced, which can cause doors slamming shut by themselves, odors lingering and heightened noise levels inside the house.

Accurate HVAC shop drawings ensure efficient air flow inside the building to give optimum comfort to its occupants.

Some of the most common mistakes in duct design include air leaks, under-sizing, protracted runs and sharply bent ends.

All of these errors can be rectified with careful HVAC design drafting.

Common Mistakes in Duct Shop Drawings

-

Non-compatible components

Without the right duct shop drawings, contractors can record incorrect requirements for air-conditioning equipment and construction material. As a result, ducts may be under-sized.

Load calculations should be done individually to cater to the varying cooling and heating needs of every room.

-

Insufficient return vents

A duct system needs both outlets and return vents for air to be sent back inside the HVAC for balanced air movement and pressure. Lack of returns causes discomfort and extra load on existing AC vents.

Ideally, every room’s supply vent should be accompanied with a dedicated return duct for balanced airflow. In spaces where there is a single central return, the air pathway should be clear and obstruction-free.

-

Air leakage

Incorrectly sealed ducts allow cooled air to leak in the walls. As much as 20% of conditioned air can leak if the duct joins are not sealed correctly.

The ducts should be sealed at installation and fastened mechanically with mastic, and not duct tapes. The joints can be further secured with sheet metal screws.

-

Length of runs

If the HVAC system is not optimized during the planning stage, the entire network ends up being too far from spaces where the cooling has to be done.

To facilitate cooling this way, longer ductwork runs are required, which decreases the overall cooling efficiency of the system.

-

Sharply bent turns

Bends that are too many or too sharp decrease the air that reaches its final destination.

So, what should one do?

How to Get Your Ductwork Installation Right

Before you begin designing a duct system, do your homework.

-

Calculate the heating and cooling load (BTU/hr) that each room requires. These units can then be translated to room-by-room air flow in cubic feet per minute.

-

After this, you must select the right product. Make sure that the appliance you pick adjusts to the outdoor and indoor design conditions. Take help of the manufacturer’s data to get this right.

All done? You’re now ready to build a duct design system!

HVAC Systems Duct Design – How to Do It Right

-

Consider the weight of the air

Basics first – air has weight.

For example, if you install a 2.5-ton AC, the nominal air flow would be around 1,000 cfm (cubic feet per minute). This means that nearly 81 pounds of air has to be pushed by the blower every minute. To move this weight around, it takes work.

-

The physics of air flow and using it to your advantage

A weight can be moved in a horizontal position without much resistance. However, to move it upward against gravity or friction requires more work. Let’s understand this with a real-life example.

A fan gives you the maximum air flow if there are no obstacles in between. However, if you introduce a cardboard tube and blow through it, the air has to flow against the pressure that builds inside. The smaller the size, the higher the pressure, and the lower the air flow.

This is the basic principle when designing a ductwork. Friction and turbulence are two factors that obstruct air flow inside a duct. As the air passes through a duct, it interacts with surfaces and fittings.

Smoother surfaces lead to better air flow and vice versa. Every fitting and duct section adds resistance to the air, along with grilles, filters, dampers and registers.

So, the air that starts at a higher pressure near the blower almost drops to zero near the supply vent. To ensure that the right amount of air is delivered to every room, the duct system needs to take pressure drops into account and create a balance from the blower to the supply vents.

Lesson learnt here?

The duct design should be smooth and obstruction-free to deliver the optimum quantity of air in every room.

Good Duct Design Tips

-

Keep it simple

Start with a simple sketch. Add obstructions along the framework. Add notations everywhere to explain different components such as outside air and duct-routing.

-

Document, document, document

If you document the entire HVAC system, you will not miss any area.

For example, if you’re planning to zone the system, note down the thermostat locations and connect these with branch lines to the main HVAC duct drawing.

This will help you shortlist damper locations.

-

Follow industry standards

To keep your equipment and ductwork the right size, follow the accepted ACCA (Air Conditioning Contractors of America) industry standards for heating, ventilation, air-conditioning and building performance.

-

Location, location, location

Ideally, HVAC equipment will be located centrally to ensure the shortest duct runs. The ducts ought to be installed within the internal walls for losing as little conditioned air as possible.

To ensure maximum efficiency, do not install ducts in attics and crawl spaces that are unconditioned. Keep elbows and bends limited to restrict the static pressure and air friction.

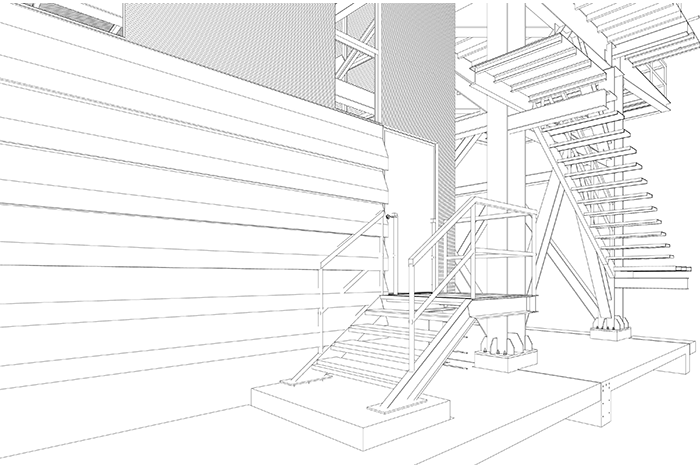

Request an architectural walkthrough of your building’s HVAC components from your duct shop drawing company. You will be able to see how your HVAC system fits with your property layout.

-

What kind of equipment & supporting systems do you need?

Larger ducts are required for heat pumps. The same goes for air purifiers that have activated charcoal filters.

Your shop drawings should be properly annotated to include these details and make sure your contractor is aware of these specifications.

Of course, it goes without saying that you should utilize the correct material, supports and fittings. The ductwork materials will vary with your budget and requirements.

Plastic flex ducts are cheaper, sheet metal is more durable and sturdy. Look for long-term returns rather than cheaper alternatives.

This will allow your design professional to create the most appropriate and industry-approved duct sizes and framework.

As a novice or beginner, designing ductwork can be a hair-raising experience.

But don’t worry. BluEntCAD is equipped to give your building a strong backbone with its shop drawing services.

We provide:

-

Consultations for renovations

-

Makeovers

-

Architectural walkthrough of your designs

-

3D renders of your plans

Get started now on receiving your detailed, accurate plans.

-

AutoCAD And RFMS: Find the Perfect Fit for Your Tile & Stone Shop Drawing Projects

AutoCAD And RFMS: Find the Perfect Fit for Your Tile & Stone Shop Drawing Projects  Exploring the Array of Tile & Stone Shop Drawing Services: Choose Your Right Solution

Exploring the Array of Tile & Stone Shop Drawing Services: Choose Your Right Solution  Mastering the Tile Shop Drawing Workflow: How Precision Prevents Costly Delays and Chaos

Mastering the Tile Shop Drawing Workflow: How Precision Prevents Costly Delays and Chaos  On Time, Everytime! Reasons to Choose BluEnt as Your Tile & Stone Shop Drawing Partner

On Time, Everytime! Reasons to Choose BluEnt as Your Tile & Stone Shop Drawing Partner

Great info. This information is very helpful for me. I agree with you, HVACs are complicated systems. Even a small glitch means that the consequences will be time-consuming, messy and expensive. Thank you for a nice post.

Excellent breakdown of the importance of accurate duct design! Proper HVAC planning and precise duct shop drawings are crucial for ensuring efficiency, comfort, and air quality. Addressing common mistakes like air leakage and insufficient returns can prevent costly issues and enhance system performance. Thanks for shedding light on these essential aspects!

Thank you! If you would like us to cover any other topic, please reach out to us at cad@bluentcad.com