If we clock back into the recent past, there have been a handful of innovative and exciting technological advancements in the construction industry. An industry that used to be reluctant to adopt new and interesting methods of conducting the same processes are now showing a keen interest in embracing it. The reason being, it has not only been enhancing productivity but also allows them to find that competitive edge. One such interesting and brand new technology is ‘Scan to BIM.’

3D laser scanning technologies have been changing the construction industry. As of now, scan to BIM is being exhaustively used in the renovation projects. With the help of the 3D laser scanning technology the data is obtained and using this data the productive 3D BIM models are built. In comparison to the traditional methods, 3D laser scanning technology is produce more accurate and faster 3D BIM models. Both external and internal laser scanning assists in developing meticulous 3D survey, which in turn helps in creating intelligent 3D models.

Before the advent of ‘scan to BIM’ technology, the architects, designers and contractors would take a set of ‘as-built’ drawings and use them to create a 3D model program. They would then develop a computer model to work from. However, post using this process for years now, they have tapped on a serious issue caused by this method – a high level of disparities has been observed between the record drawings and the real environment used for construction.

While adjustments could be made to sheets and wood to fit them correctly, it would be both a very laborious and a costly task to make similar adjustments to other materials such as steel, mechanical instruments, glass or concrete. Using brand new expensive equipment into a smaller space is still observed to be a tormenting task for the engineers and designers.

There were several traditional methods that came with their own challenges. Hence ‘Scan to BIM’ is seen as one of the most brilliant innovations.

One of the first 360-degree scanning methods used was in 2004 also known as the “360 Degree Scans”. Before the first ever 360-degree scanner came into existence, the scanners would use scanners that had only 120-degree scan aptness on the vertical axis. Many organizations built straight scanners to make the task of taking scans of anything that is above their heads a lot easier. With the 120-degree scanner they would need to bevel it back and scan at a steep angle.

Around 2006, Time-of-Flight scanner was invented. This scanner took around 45 minutes to an hour to finish a 360-degree scan. The engineers and designers could do maximum 8-10 scans a day. This in itself was an achievement. However, thanks to the new technology, today it is being done in about 10-15 minutes. This also depends on the density they need.

Phased-Based Scans was introduced in the year 2008. It is still considered to be more effective than the other two scanners and has the potential to scan just about anything in a good amount of time. When say, scanning a pathway, phase-based scanners are able to scan ¼ inch by ¼ inch and have the preparedness to collect 2,000,000 points per second. As any standard users would require it to be, this scanning technology is noted to be quick and dense.

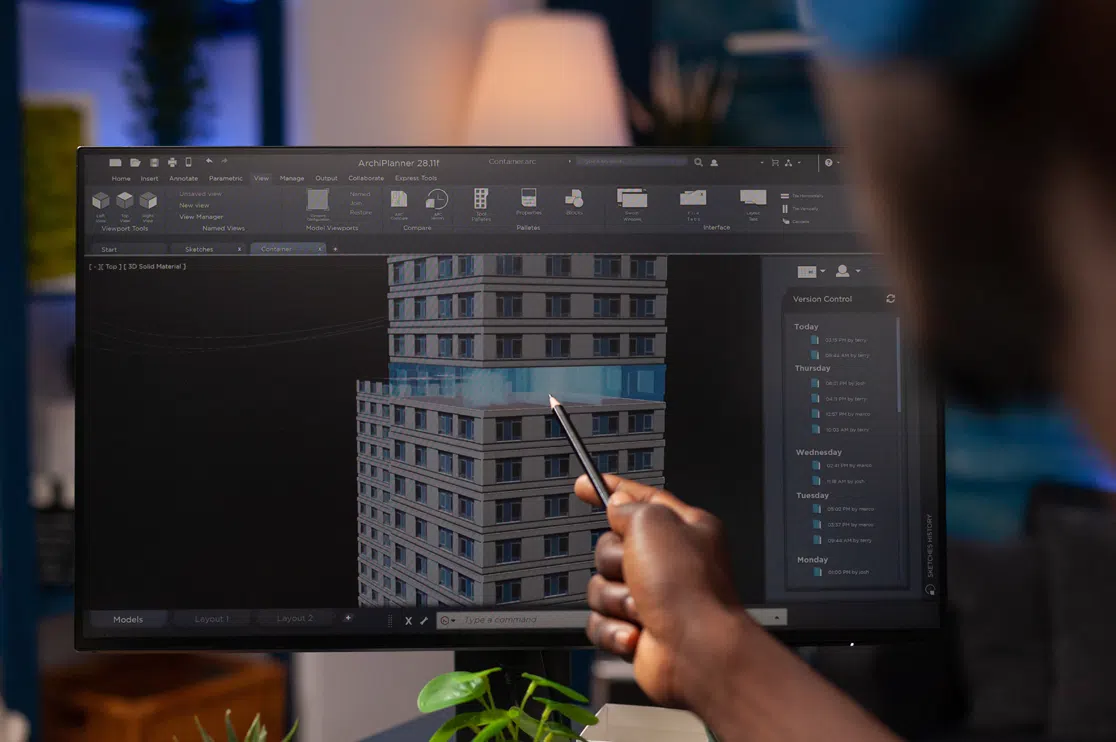

Now we have one of the biggest innovations in the scanning sector: ‘Scan to BIM‘. Many organizations have started to adopt this 3D scanning technology. By using this technology and creating a productive 3D BIM any project can be constituted and managed in a much more efficient and precise form. Through 3D laser scanning facility, the utmost accurate dimensions are taken of even the most complex environments and geometries. Both the interior and exterior of the structure is taken to build an accurate and intelligent 3D BIM model along with 2D as-built drawings, directly taken from the scan data.

Scan to BIM is a big innovation already mastered by BluEntCAD. We have specialists with extensive experience in ‘Scan to BIM‘. Connect with us for your upcoming projects. We promise to save you those extra quota in construction costs.

How AI BIM Modeling Shaping the Future of Residential Construction?

How AI BIM Modeling Shaping the Future of Residential Construction?  How BIM Services Enhance Collaboration, Design Choices, and Project Efficiency for Architects? – A Guide

How BIM Services Enhance Collaboration, Design Choices, and Project Efficiency for Architects? – A Guide  How is Artificial Intelligence in Construction Design Transforming Architectural Landscape?

How is Artificial Intelligence in Construction Design Transforming Architectural Landscape?  BIM Coordination Benefits for Contractors in the Preconstruction Stage

BIM Coordination Benefits for Contractors in the Preconstruction Stage